Linerless Labelling - Environmentally Friendly

LINERLESS LABELLING - ZEBRA - HONEYWELL - TSC

Environmentally Friendly

Supplies Solutions

As concerns for environmental sustainability continue to grow, companies are looking for innovative strategies to decrease their environmental impact while also increasing operational efficiencies and productivity.

To support your sustainability goals while keeping your operations running effectively, Zebra offers innovative, environmentally friendly thermal supplies. Our line of eco-friendly Zebra Certified Supplies enables you to demonstrate your dedication to the environment as a globally responsible

corporate citizen, while delivering the performance you have grown to know and depend on from Zebra Certified Supplies.

What are Linerless Labels?

Unlike standard labels, linerless labels do not have a liner with a release coating that enables the label to peel away and separate the adhesive from labels underneath it on the roll. Similar to a roll of tape, linerless labels feature a silicone release coating on the top layer of the labels and special adhesive that enables them to peel away from labels underneath.

Key Benefits of Linerless Printing

Incorporating a linerless printing solution has many advantages:

Sustainability

- Reduces waste to positively impact the environment

- Labels are fully recyclable in the cardboard waste stream

- Using ~ 40% less paper than comparable linered labels

- Linerless labels are Certified as Carbon Neutral

- Decreases weight in mobile printers and reduces label roll shipping as linerless rolls weight up to

40% less than traditional, pressure-sensitive labels with a liner

Efficiency gains

- No need for peeling labels

- No disposing of the backing liner

- Fewer boxers of labels to transport and store

- Improves productivity as media rolls contain 50% more labels and require fewer media changes

- Increase uptime, reduce the need for changes and minimize storage

- Maintaining Scanning and traceability properties as linered labels while using less raw materials

- Shipping more efficiently without compromising on performance

- Reduces workplace slip hazards from liner piles that collect beneath printers

Flexibility

- Label size needs can vary right up the point of printing

- Can be cut to any length, eliminating the need to maintain labels stock of different sizes

What are the Challenges to Linerless Solutions?

With all the advantages, implementing a linerless solution can be tricky. First, you need to ensure that your printer and linerless labels are compatible with each other. One key factor is to ensure your linerless labels have been fully tested with your specific printer.

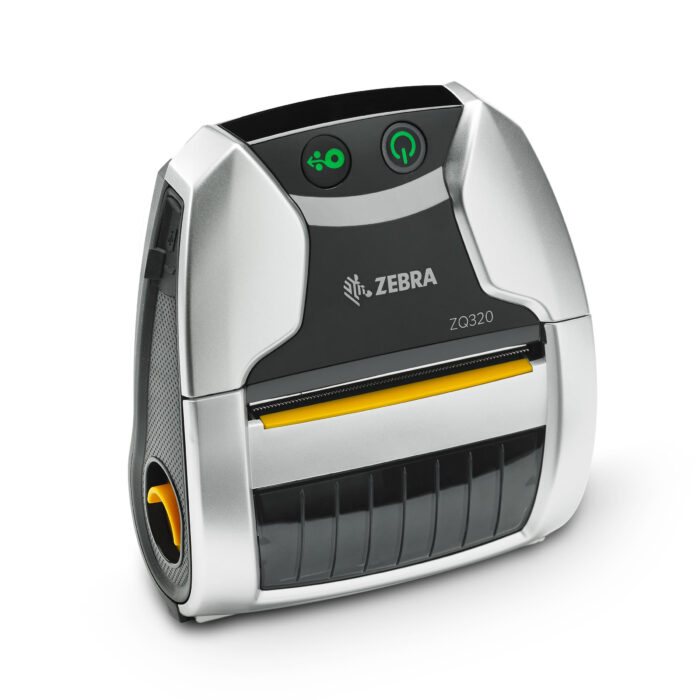

Regular thermal desktop and mobile printers cannot accommodate linerless labels. Desktop and mobile linerless printers feature a special platen roller with a non-stick surface to reduce the instances of the label adhesive sticking to the platen roller. As labels are printed, the adhesive comes into direct contact with the platen roller because there is not a liner to serve as a buffer. Also, desktop linerless printers feature a special cutter to cut the labels to size as they are produced.

Linerless materials perform much different in desktop printers than in mobile printers, and in printers from varying manufacturers. Printer brands have differences in form factor and mechanical design, requiring specific formulations in the adhesive and label coating.

MaterialName |

PrintingTechnology |

MaterialType |

Adhesive |

Key Features |

|

Z-Perform 1000D PF Label |

Direct Thermal |

Phenol-Free Paper |

Permanent Acrylic, Removable, High-Tack, or Deep Freeze |

Engineered with phenol free developers, offering an ideal substitute to standard labels with phenols used for shipping, receiving, and work-in-process |

|

8000D Linerless Label |

Direct Thermal |

Paper |

Permanent Acrylic or Removable |

Features a silicone release top-coating and special adhesive that enables the labels to peel away from labels underneath it with no liner needed. Eliminates liner waste found with standard labels. |

|

PolyE 4000D Label |

Direct Thermal |

Polyethylene |

Permanent Acrylic |

When used with a polyethylene bubble mailer, consumers can easily recycle, reducing dirty recycling and the amount of packaging going into landfills. |

Linerless Solutions

To help you achieve your goals with linerless labeling, We offer the following linerless solutions